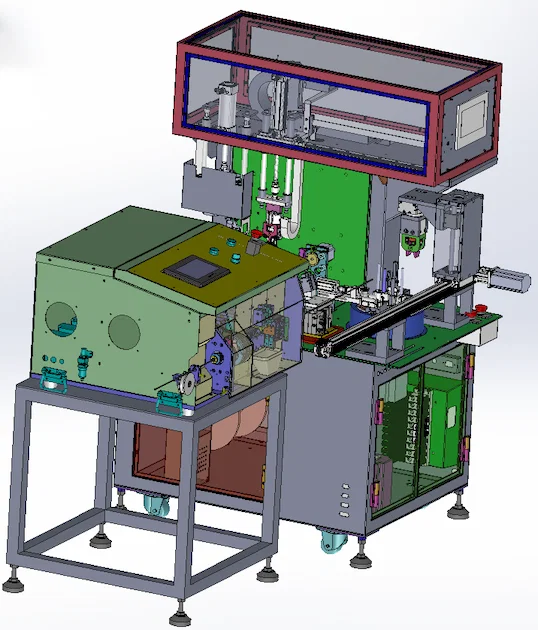

BWM0001-blister winding machine is mainly applied to cut fixed length and package blister of plastic filament, like grass trimming line and nylon monofilament. The machine can automatically cut, wind and feed the wire through parameter setting and PLC system

Filament diameter:1.0~5.0 mm

Speed of feeding:≤ 2 m/s

Blister diameter:80~200 mm

Hole diameter:≥ 45 mm

Height of Blister:20~100 mm

Production rate:6~10 Pcs/min(based15mlength)

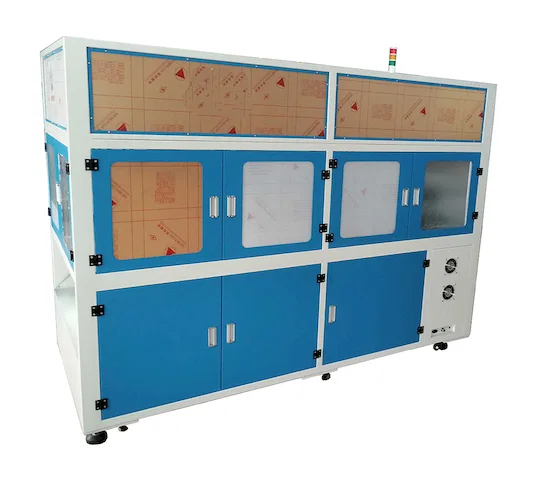

Operator required:1 person(can operate 2~4 units)Length of machine:650 mm

Width of machine:550 mm

Height of machine:1800 mm

Weight of machine:Approx200 kg

Power supply:1 Phase AC 220V 50Hz 2Kw

Compressed air:0.4~0.6 Mpa1 m3/hr